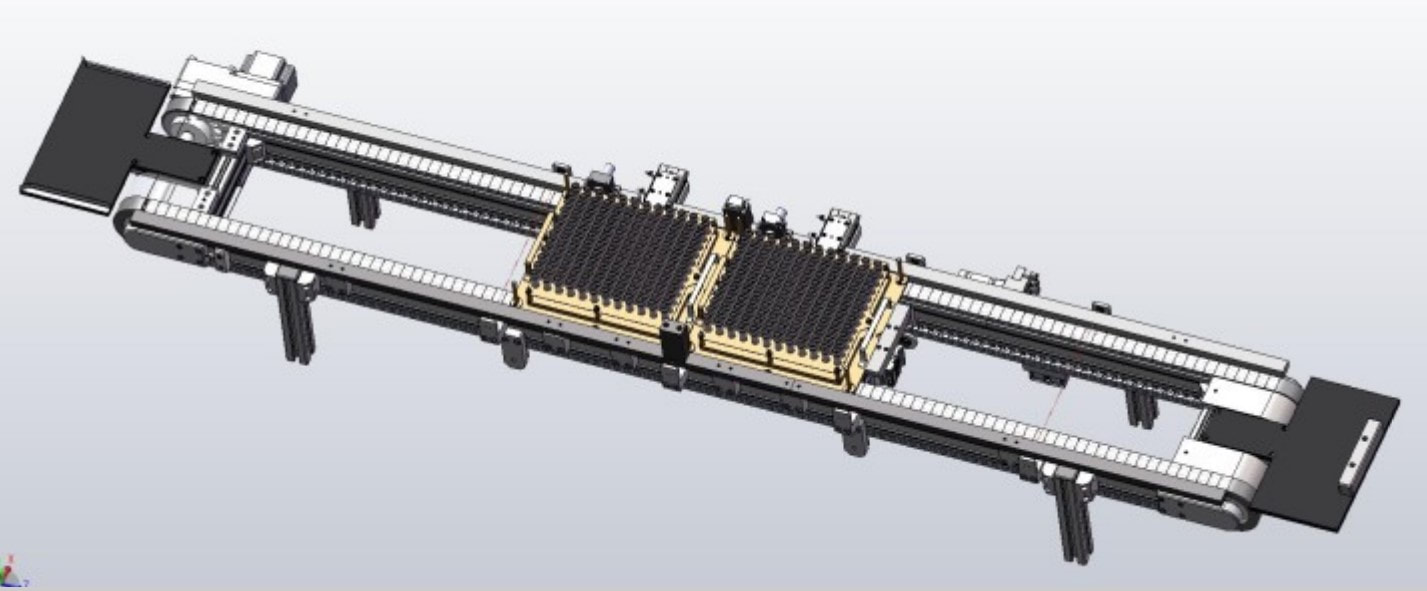

TRIPLE DRAWER, VERTICAL

|

DUAL DRAWERS

|

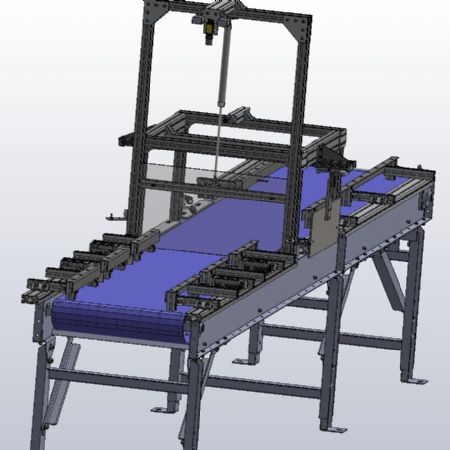

PLASTIC TRAY CONVEYOR

|

RUBBER CONVEYOR HEAVY PARTS

|

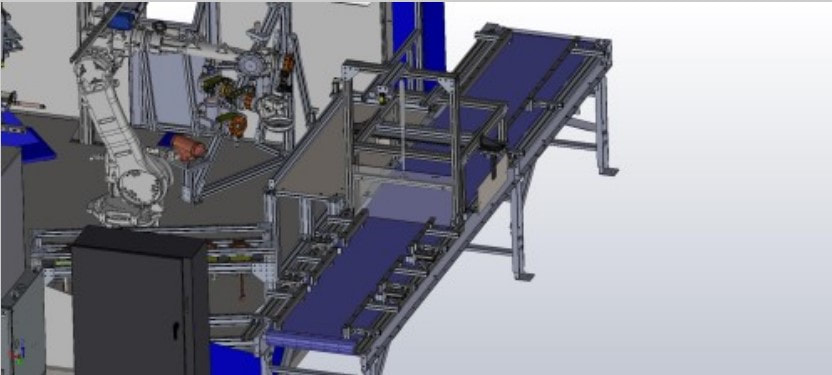

CONVEYOR FOR FEEDING/METERING TRAYS

|

CONVEYOR FOR FEEDING/METERING TRAYS

|